SERVICES

Soffieria Bertolini provides technical and scientific supports in cooperation with the Turin University Chemical Department.

Product development in cooperation with Turin Politech University (FEM model, algorithms development).

The most required services are the following:

- USP 1660 durability test – extractable & leachable Nitrates in WFI.

- Aluminum leaches.

- Morphological and elementary analysis (i.e. SEM-EDX, TEM, X-ray Diffraction; IR-Microscopy, Raman).

- Customized product design.

Our glass experts will be at your disposal for:

- New packaging solutions.

- Quality assistance (Including glass packaging sorting out at your plant).

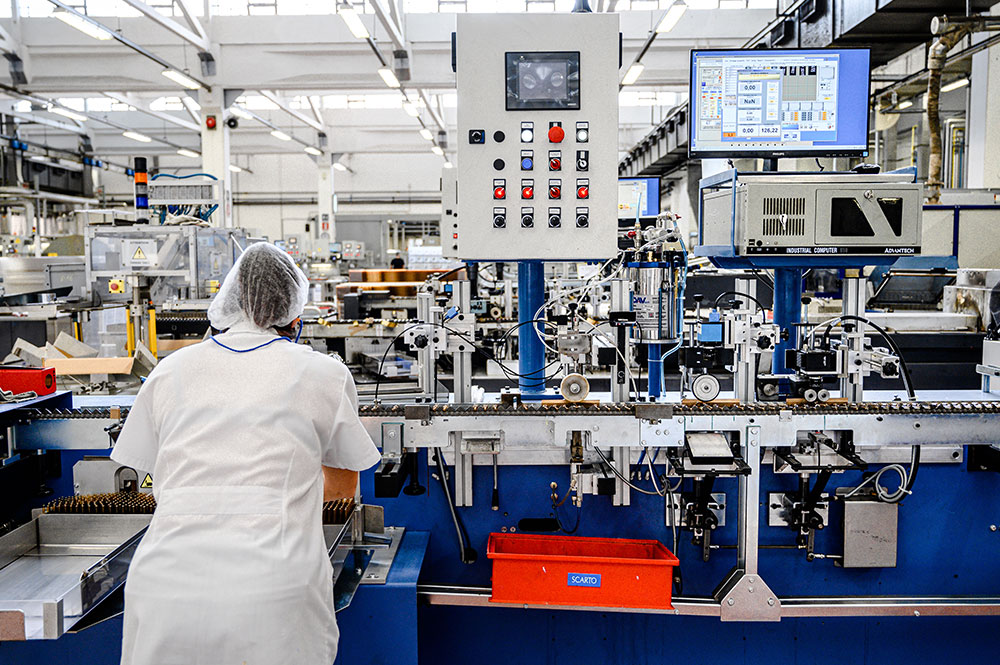

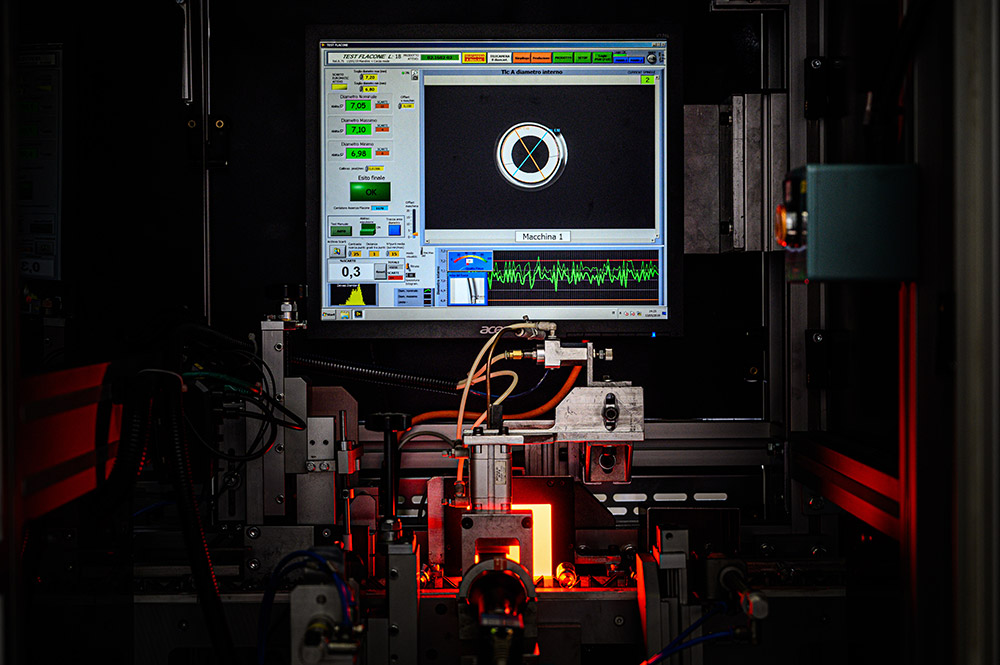

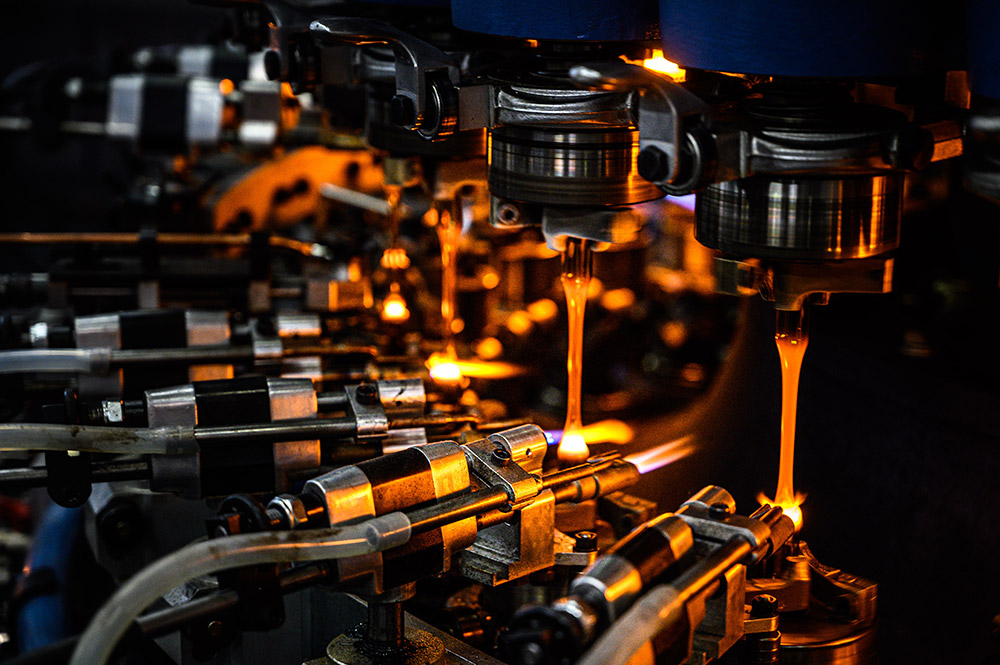

PROCESS MONITORING

Our main parameters are continuously monitored during manufacturing process.

Six Sigma Method

We use statistical criteria to investigate and minimize defects from the manufacturing process. A further step can be achieved by using DOE (design of experiment).

ACHIEVEMENTS

Cosmetic Defects Control

In order to check 100% cosmetic defects (scratches, cracks, spots, etc.) we use the dedicated camera installed on the manufacturing line, just before final packaging

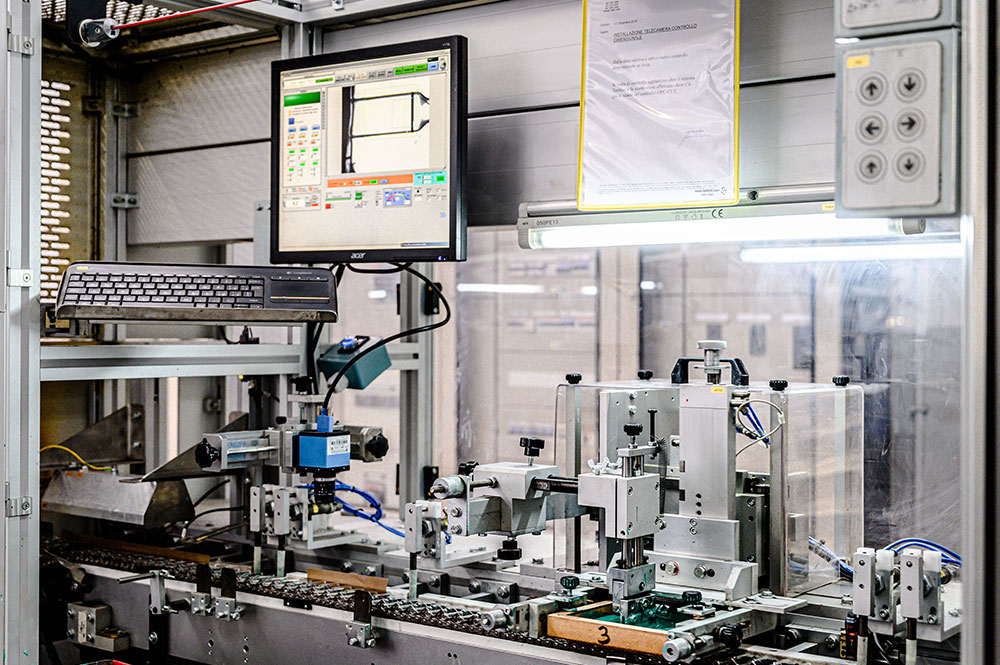

Printing Control

We check the printing area assuring the positioning and completeness of text and variable data, by means a dedicated camera.

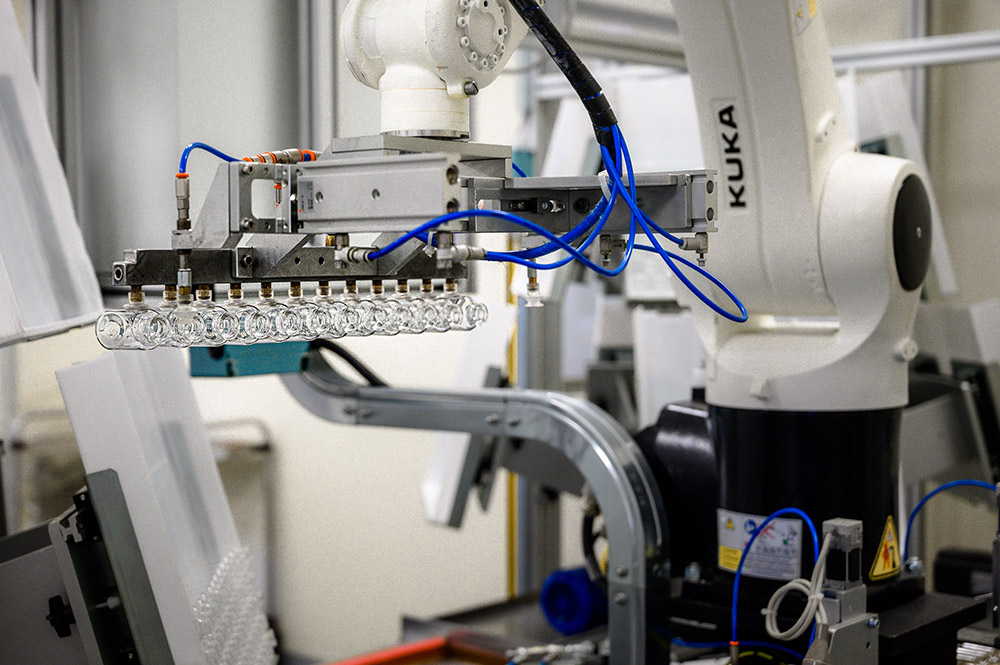

Automatic Packaging

To further reduce cosmetic defects.