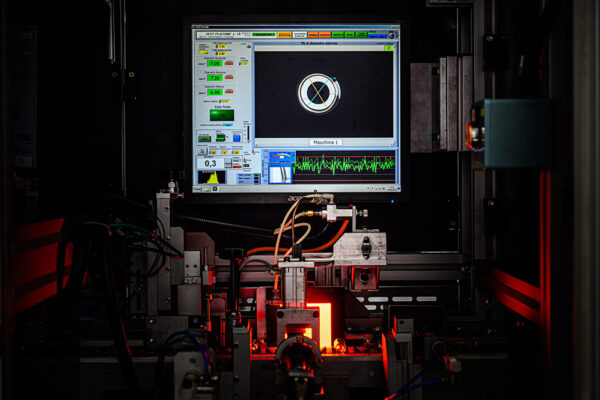

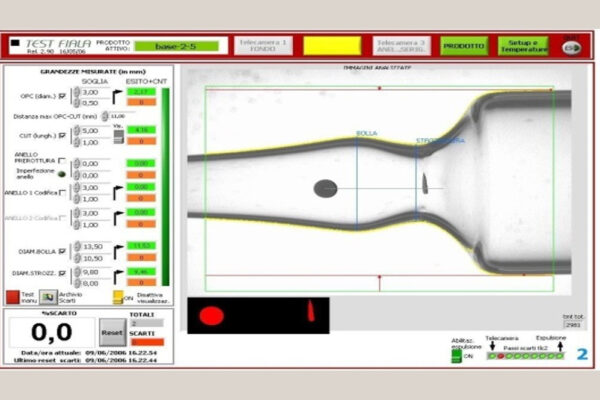

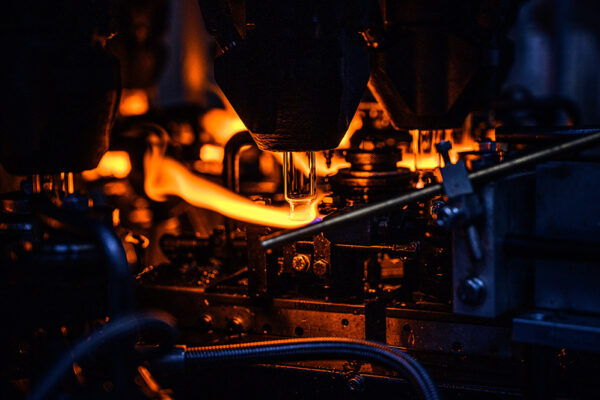

SB VISION SYSTEM:

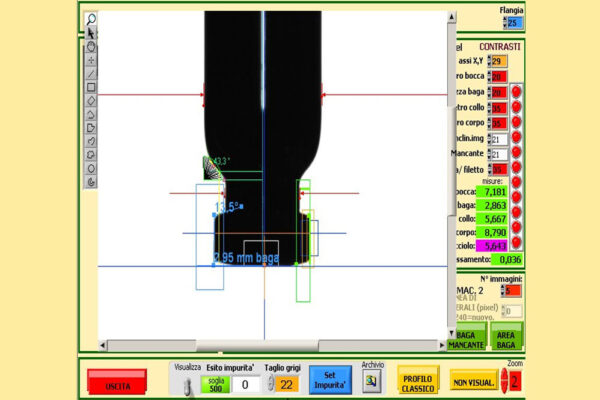

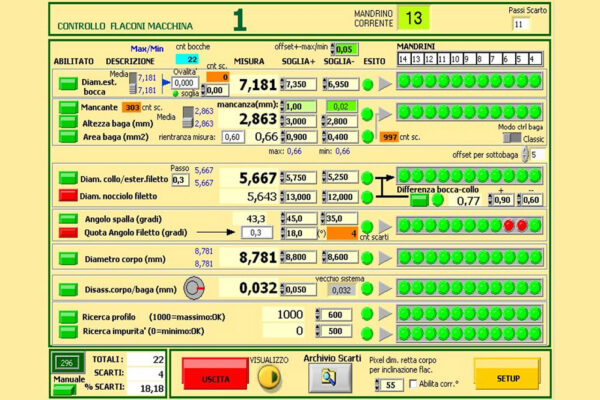

COSMETIC / DIMENSIONAL DEFECTS CONTROL

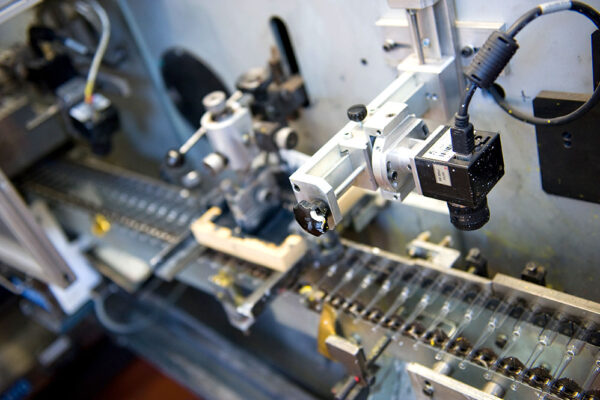

To check 100% dimensional and cosmetic defects (scratches, cracks, spots, etc.) by means of a dedicated camera installed on the manufacturing line.

Sw COPYRIGHT Vial 01/17 and Ampoule 01/17.

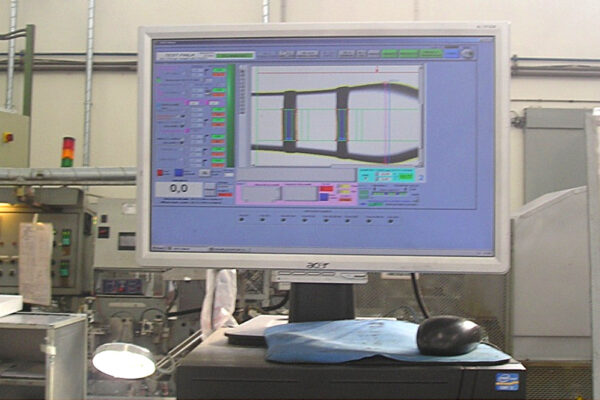

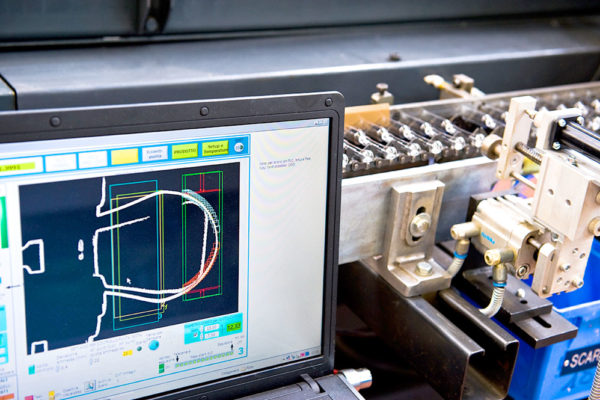

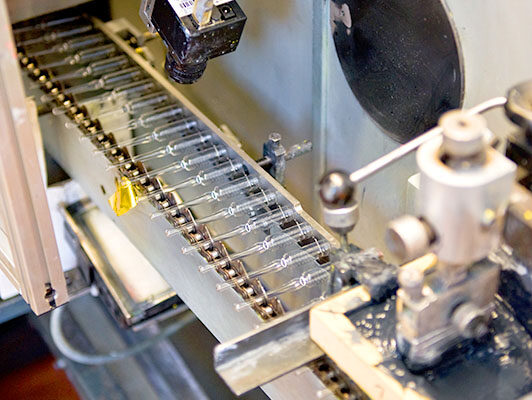

PRINTING CONTROL

To check the printing area assuring the positioning and the completeness of the text and variable data (batch no and expiry date), by means of a specially developed software installed on a dedicated camera.

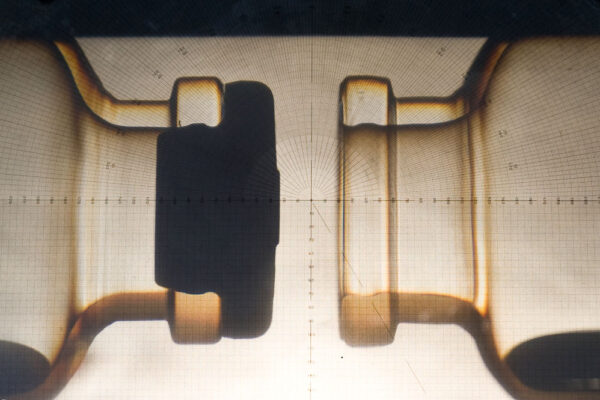

ENHANCED NECK ID CONTROL

Camera equipped with new optics capable to improve the precision of the measurement (parallax error free).

BOTTOM/BODY RADIUS CONTROL

Goal: to reduce the bottom breakages through a 100% control of the bottom radius.

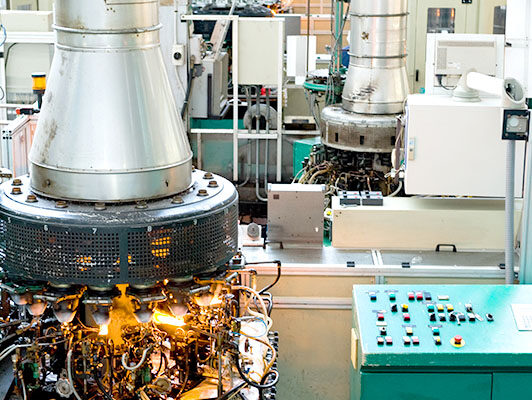

INTERNAL TREATMENT SYSTEM – SB PATENT

Cameras capable to detect the quality of the internal siliconization.

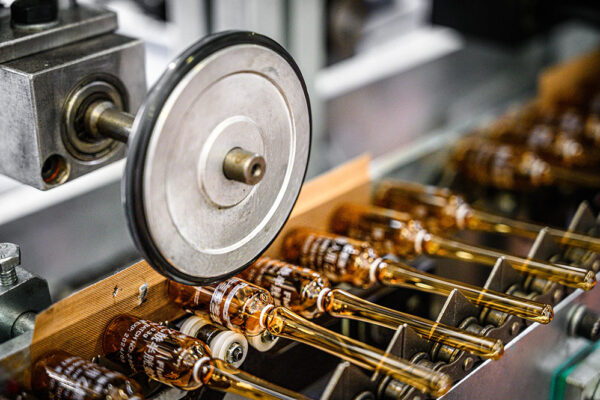

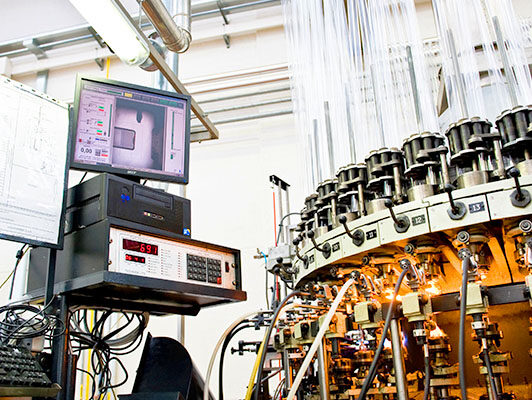

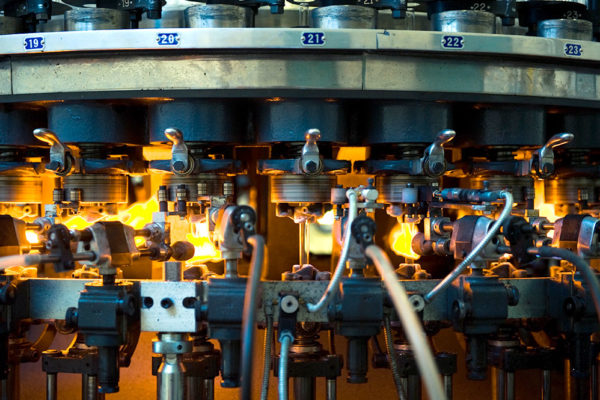

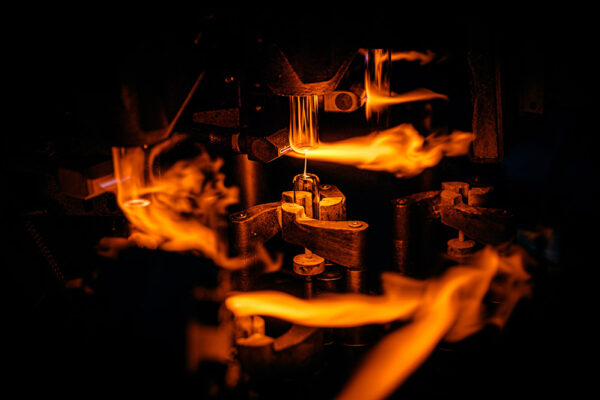

AMPOULES

High speed production lines fully equipped with automatic camera system capable to:

- 100% dimensional detection without metal contact = breaking risks reduction.

- 100% breaking systems (OPC-CB), code rings detection performed by new generation camera systems.

- 100% printing and cosmetic detection.

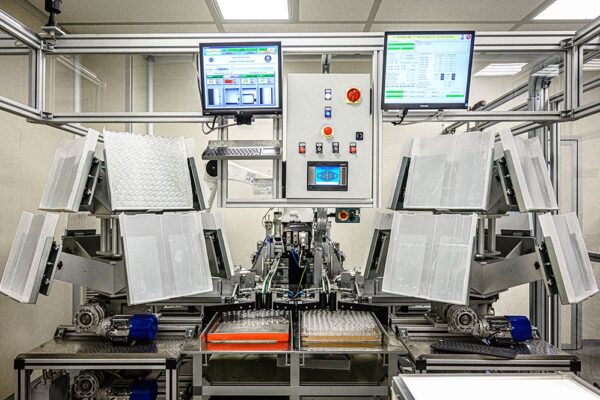

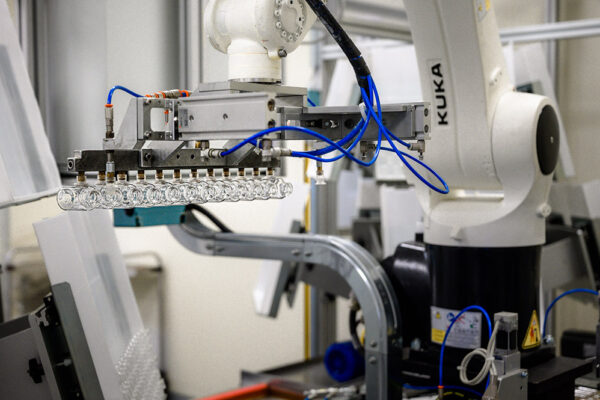

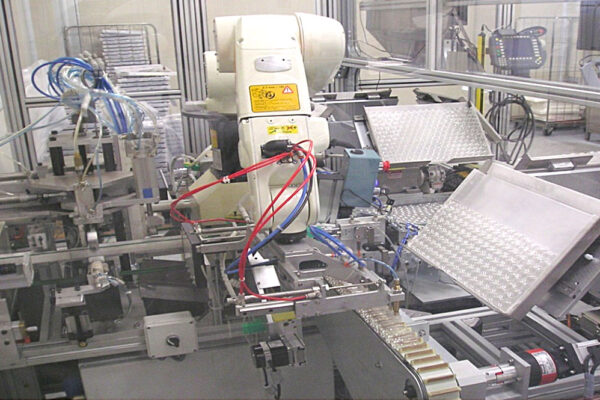

VIALS

Fully automatic packing device:

- Glass to glass contact avoided (cosmetic quality improved =Japan Quality).

- Risks of micro cracks strongly reduced.

CP – CPk real time process capability analysis and report.

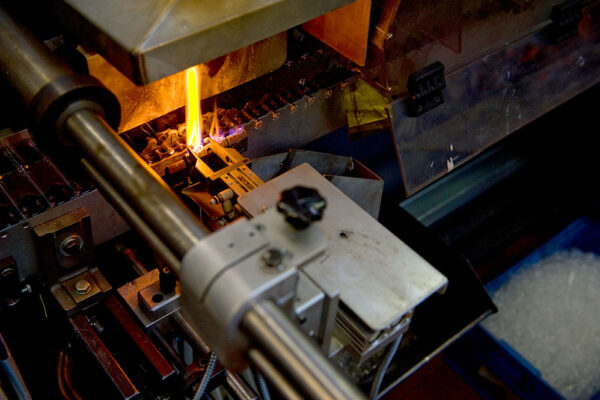

CARTRIDGES

High speed production lines fully equipped with automatic camera system capable to:

- 100% dimensional detection.

- 100% printing and cosmetic detection.